Developing the future cab industries

Umeå cab manufacturing site is located in the northern parts of Sweden with approximately 1500 employees. It supplies the Volvo Group with premium cabs for the heavy duty Volvo trucks but it is also a center for developing the future cab manufacturing industries. During a visit in the Umeå factory it is easy to see the advanced automated processes where employees and robots work side by side to secure quality and delivery precision in the best way.

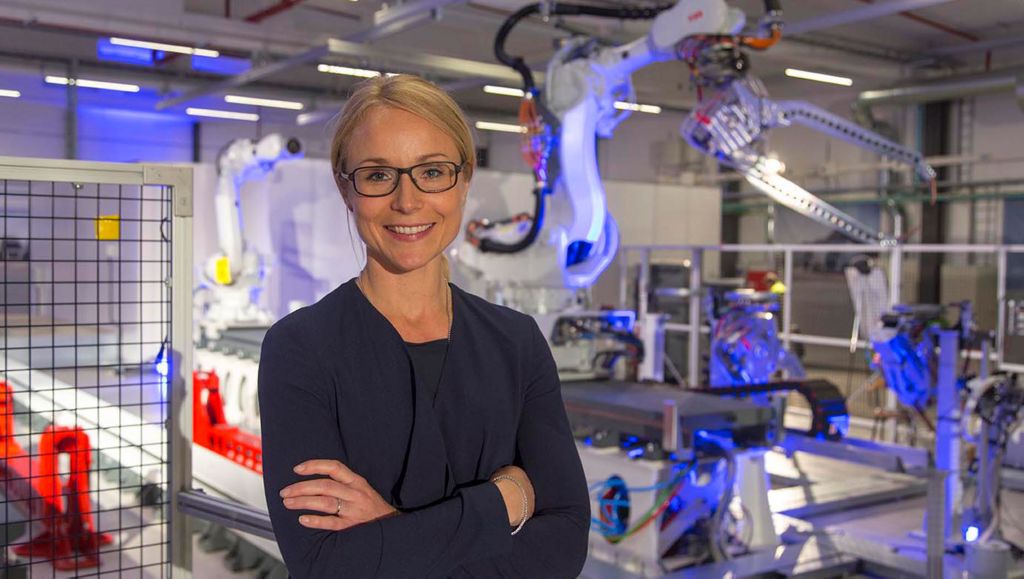

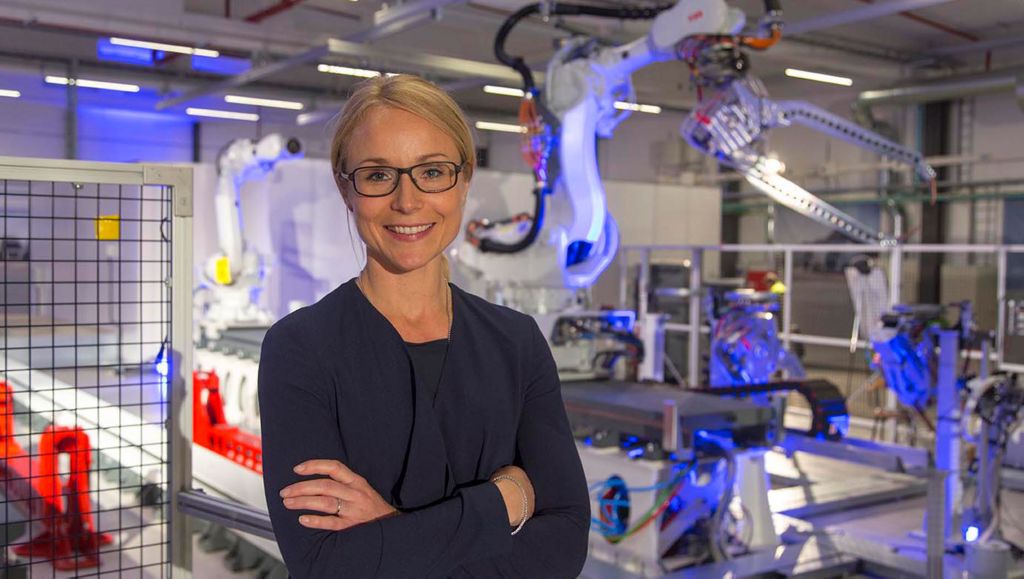

“To work in a site with such a high technological level like Umeå is incredibly developing for engineers like me and my team. We are a high volume plant delivering premium cabs to our customers and that responsibility is both exciting and demanding! With all the technologies that are now rapidly developing within Industry 4.0 we see enormous possibility of even further development in our already modern plant!, says Sandra Finér.

She is responsible for Engineering and Maintenance, and including that Volvo Cab Competence Center, located in Umeå, with the main task to support the development of new product and process concepts for cabs when it comes to stamping, body in white and surface treatment.

“As a part of the global industry organization GTO, employees from Umeå with specialist knowledge in different areas gets to travel a lot to support other plants. Interacting with our colleagues from the rest of the world is definitely one of the advantages of belonging to a global organization,” she says.

“I am passionate about technology, leadership and have a belief in every individual’s ability and potential. Our mind-set with continuous improvement and finding new ways of working is always inspiring. I truly am proud to work for a company like the Volvo Group that lives by its values,” finishes Sandra Finér.