Preventing Crashes and Saving Lives: Volvo Trucks Drives Safety with Industry-First Innovations

Volvo Trucks, one of the world’s largest commercial heavy-duty truck manufacturers, has a long-standing commitment to safety that can be traced back to 1959 to the time Volvo invented the three-point seat belt and gave the patent away for all to use.

That safety focus is evident in Volvo Trucks’ all-new VNL and VNR models - two next-generation heavy-duty trucks that offer a suite of digital and mechanical safety systems. Among industry firsts from Volvo Trucks: side curtain air bags for both the driver and the passenger, electronic parking brakes to avoid accidental roll aways, an automatic emergency call function, and a high strength steel cab with ultra-high strength steel reinforcements to protect occupants in case of an accident.

“We are very proud to introduce these safety features in North America because safety is in our Volvo DNA and at the heart of every truck we build,” says Peter Voorhoeve, president of Volvo Trucks North America. “At Volvo Trucks, we have a vision for zero accidents, because it’s the only number that’s acceptable.”

Industry-First Safety Innovations:

Side Curtain Airbags: Raising the Bar for Rollovers

Volvo Trucks is the first heavy-duty truck manufacturer in North America to offer integrated side curtain airbags as an option. This feature is designed to deploy in a rollover and protect both driver and passenger and is automatically triggered by a tilt angle. Rollovers are among the most dangerous types of crashes, accounting for roughly half of all truck occupant fatalities and these airbags provide critical protection for both the driver and passenger.*

High-Strength Steel Cabs

Volvo leads the trucking industry as the only manufacturer to build every cab entirely from high-strength steel. The cabs are designed to absorb and deflect the energy of a crash while maintaining cab integrity to protect occupants, reducing the chance of injury. Volvo’s all-new VNL and VNR cabs use 33% more ultra-high strength hot stamped steel than previous generations, reinforcing key areas above driver and passenger doors to improve rollover protection. By using stronger materials more efficiently, Volvo enhances protection while keeping cab weight down.

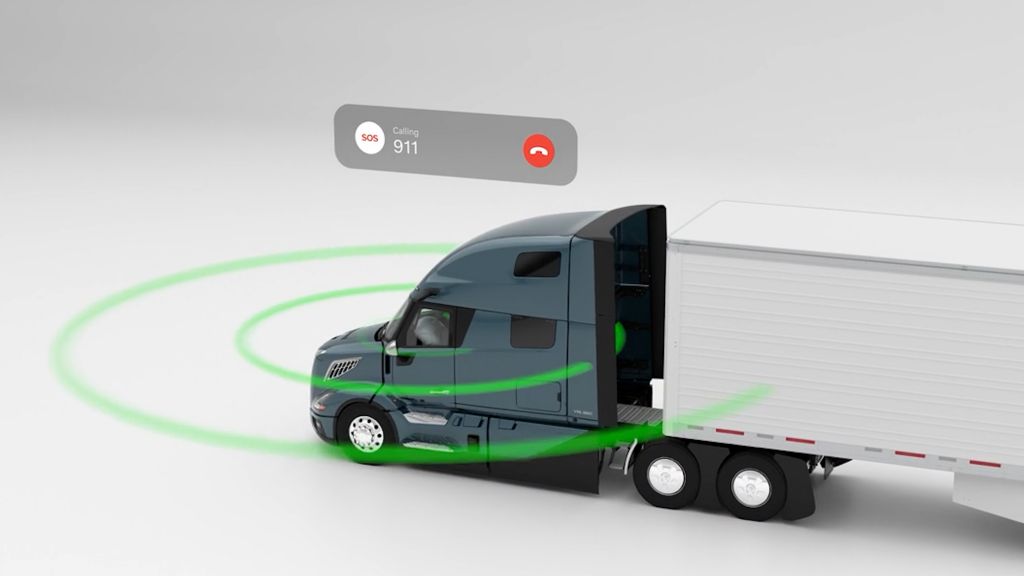

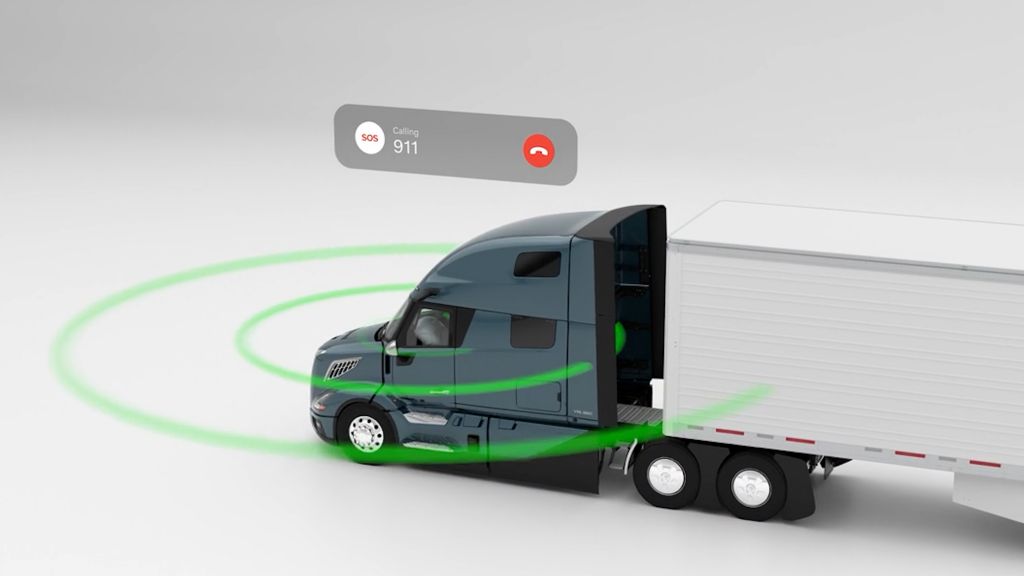

E-Call: When Every Second Counts

In 2024, Volvo Trucks introduced another industry first for heavy-duty trucks - the E-Call emergency response system. In the event of a serious accident like a rollover or airbag deployment, the truck automatically calls 911 if SOS signal coverage is available, sharing its precise GPS location with first responders. This promotes faster response times, especially if the driver is unable to call for help. A driver can also manually activate E-Call in a medical emergency or precarious situation if they have the SOS call option.

Tackling Rollaways: New Electronic Parking Brake

Another safety feature is Volvo’s new electronic parking brake, standard on all new VNL and VNR models. The next-generation parking brake engages automatically if the truck is put in neutral and the driver door is opened. Auto-release occurs when the truck is placed in gear and the accelerator is pressed. If an accident occurs, the brake engages immediately and the transmission shifts into neutral to stabilize the truck.

Additional Safety Innovations:

Drivers of today’s heavy-duty trucks are supported by advanced safety systems including collision avoidance technology and pedestrian detection that act like an extra set of eyes. New collision avoidance technologies can detect vehicles, pedestrians, and cyclists around the truck, at certain distances, helping prevent crashes before they happen. By combining radar and cameras, these systems alert drivers to potential hazards ahead and on either side of the vehicle. These innovations in the all-new VNL and VNR are expected to dramatically reduce the number of rear-end collisions.

“Everything we do - every innovation, every test, every improvement - is about people,” said Voorhoeve. “We don’t just build trucks. We build trust, safety, and a future where every road is a little bit safer.”

Facts: A Safer Future, Mile by Mile

June 26, 2025

To learn more about Volvo Trucks North America, visit the company website.

High-resolution images associated with this press release and others are available at https://press.volvotrucks.us/.

For further information, please contact:

Cecilia Carlsson

Director Brand, Marketing & Communication

336.230.4788