Thermal management is cool

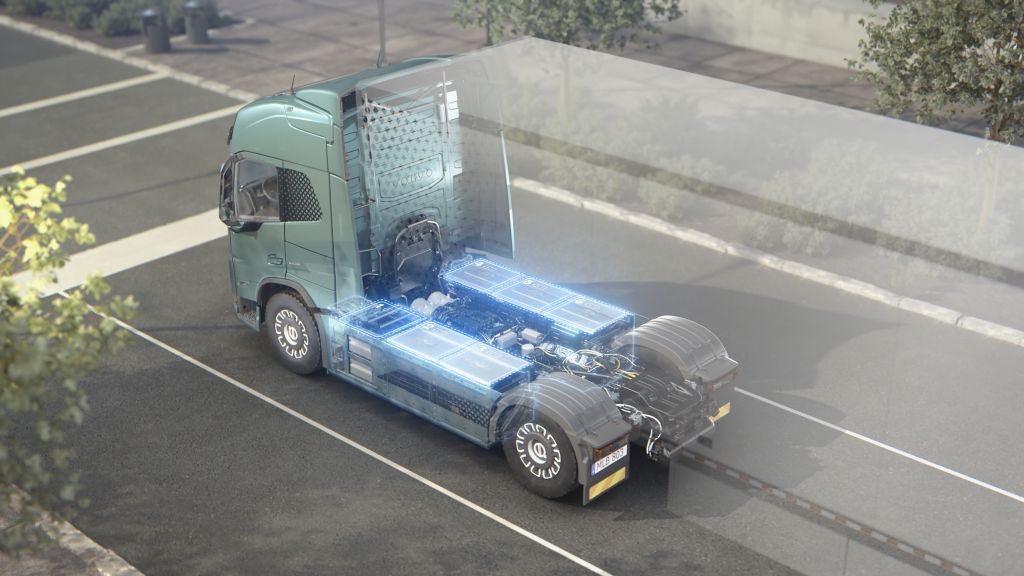

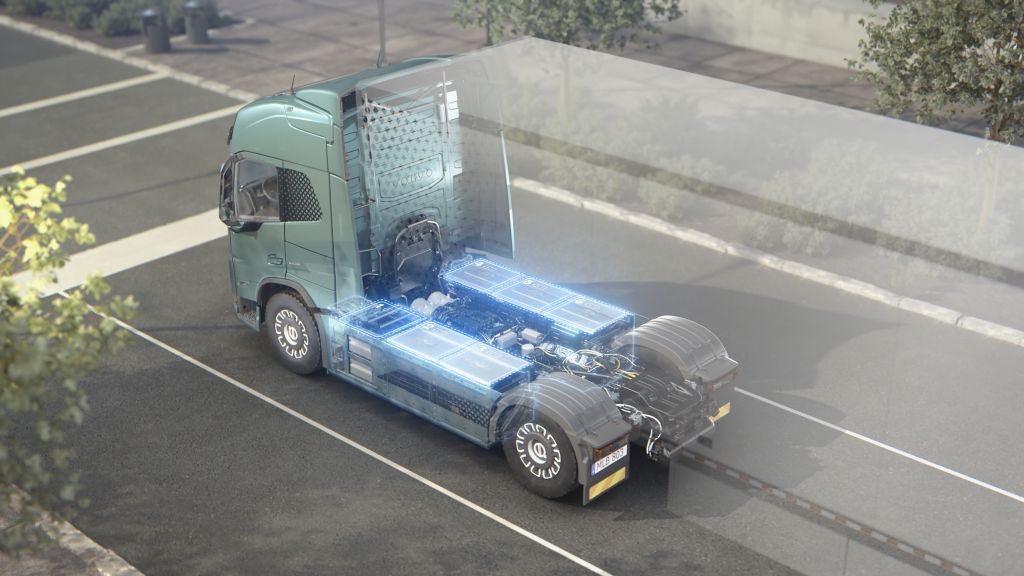

Battery lifespan, safety, and performance are directly affected by this system, and it also represents the second highest use of energy in an EV battery pack after the electric motor used to propel the vehicle. This is why Volvo Group engineers are so focused on creating the optimal conditions for the battery pack.

So, how do you manage the temperature of the battery pack? And more important still, how do you do it so that the battery life, safety, and performance are optimized?

Engineers at Volvo Group have been researching a wide range of improvement pathways for thermal management, starting with the actual design and packaging of the battery pack itself, and the airflow around it. But without onboard sensors constantly monitoring the thermal state of the battery pack there is no way to manage it. So, sensors play a vital role in this process.

Sensors can range from simple temperature sensors to gas sensors that feed into a thermal runaway alert system that is designed to meet Electrical Vehicle Safety – Global Technical Regulation (EVS-GTR) standards.

Staying cool under load

Apart from the onboard heat and gas sensors, the thermal management system’s main hardware is the cooling plate, which does exactly what you might think – it cools the battery using heat dissipation and ambient conditions. The cooling plate plays an increasingly important role in pre-thermal conditioning of the battery packs to optimize charging time. A battery pack at the right temperature charges faster than an overly hot or cold one, and as the battery is charged and begins to heat up, regulating the temperature with the cooling plate ensures a constant and optimized rate of charge.

Another vital part of thermal management is in the design of the battery pack’s insulation, which can greatly affect performance levels. Think of it this way – some parts of the battery are more open to ‘fresh air’ and ambient cooling than others – and the thermal management system plays an important role in normalizing the overall temperature.

And as thermal management plays such an important role in safety, preventing the potential for what is known as thermal runaway, it is vital that the cooling plate and sensors operate on a redundant power supply to ensure that any deviations from normal operating conditions are communicated via the onboard thermal event safety warning systems.

Volvo Group’s approach to thermal management ensures predictable battery charge and discharge behavior and optimizes overall performance and the longevity of the battery pack. You can think of the thermal management system as the equivalent to the oil pressure and coolant temperature gauges on a traditional internal combustion engine. Without it you will not get the most power or performance from your drivetrain.

Would you like to learn more about how Volvo Group is engineering the future of mobility? Check out our Sustainable Solutions and discover more about our approach to electromobility.