Skövde factory F 40 years

The history of the Skövde plant, however, dates back all the way to 1868. John G Grönvall started Sköfvde foundry and mechanical workshop that year and up until 1907 the main products were frame saws, iron stoves and turbines. The first engine was produced in 1907.

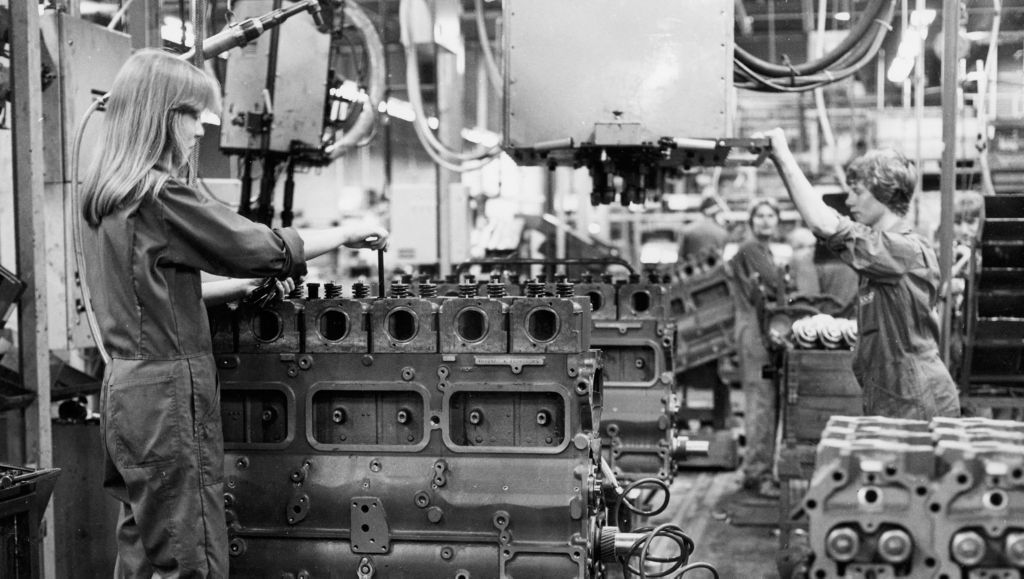

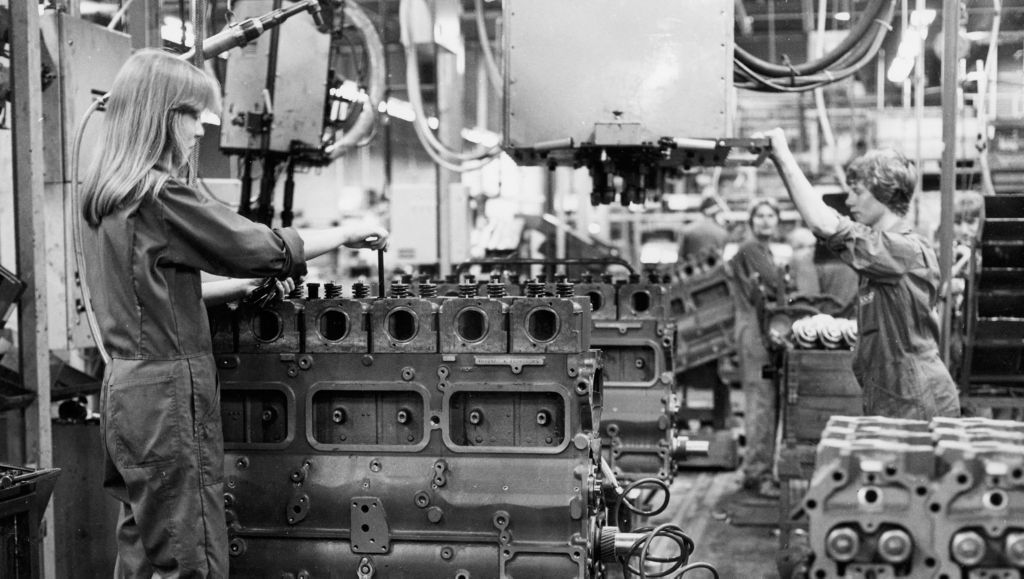

During the 1920s, Volvo became an important customer and in 1935 AB Volvo bought its own engine production factory. The construction work of a new engine assembly factory started in 1973 and took two years to complete. This is today part of the GTO Powertrain Production plant in Skövde. In October 1975 the assembly factory F was ready to produce engines at an annual capacity of 60,000 units per year. The factory had space for testing, painting, load area and an engine store. New features included stationary carriers and the final assembly was done on engine racks to avoid reloading before testing and delivery.

The D7 and D100/120 were the first engines to be produced at the assembly factory. Since then extensions of the factory have been completed in steps; in 1983 with an automated warehouse, in 1984 with space for CKD packaging and in 1987 with assembly for the D16 engine for the new Volvo FH16 – a 200 MSEK investment for the Skövde plant. In 1990, the assembly of the D12 engine started.

Today’s assembling at the F-factory consists of the HDE13 and HDE16 engines. The entire engine plant has some 2,800 employees. Happy 40th anniversary!